DDESP-FM-V2

Geometry

RectangularTip Radius (nm)

Nom: 100

Max: 150

Frequency (KHz)

Nom: 105

Min: 80

Max: 130

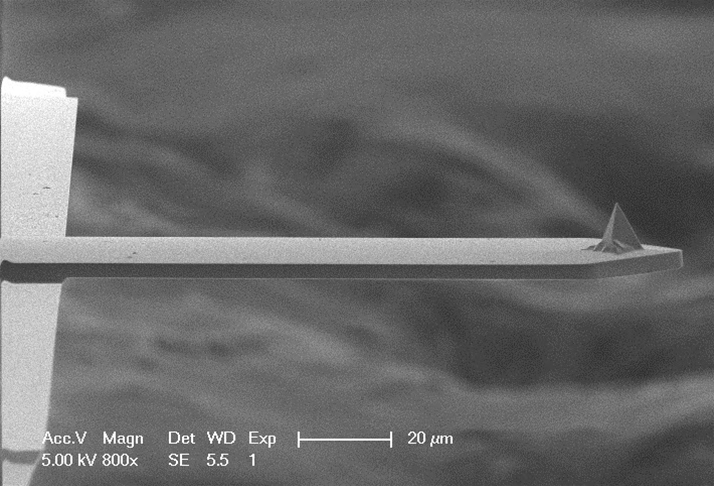

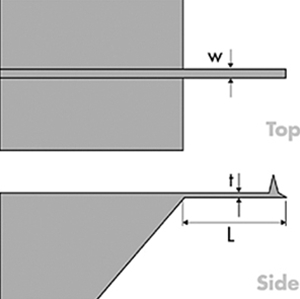

Length (µm)

Nom: 225

Min: 215

Max: 235

Spring Const (N/m)

Nom: 6

Min: 3

Max: 12

Width (µm)

Nom: 35

Min: 33

Max: 37

Order a free DDESP-FM-V2 sample

Price: $1,400.00 (USD)

Sold in packs of 10

Questions? Free, Online Consulting

Overview

Bruker's popular DDESP-FM-V2 electrical probe provide both fantastic wear resistance and robust conductivity due to the hard and highly conductive tip side doped diamond coating.

Perfect for applications such as C-AFM and PeakForce TUNA, SCM, SSRM, and PFM.

For a stiffer cantilever version of this probe see DDESP-V2.

Probe part numbers ending in -V2 provide:

Tighter dimensional specifications for improved probe to probe consistency

More precise alignment of the tip to the cantilever apex

Improved aesthetics

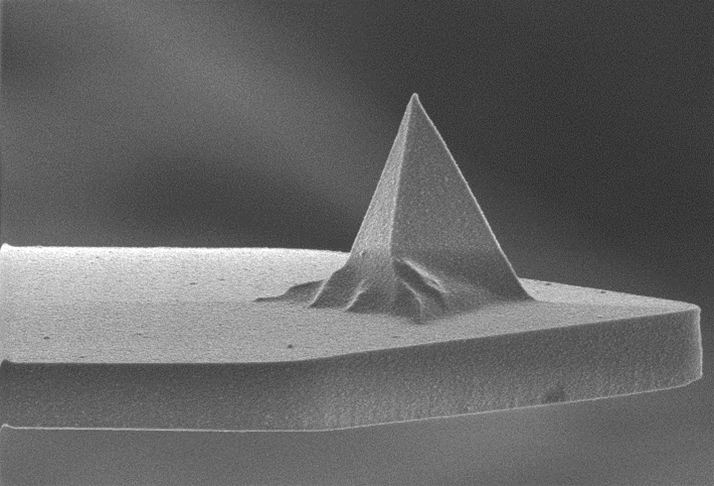

Tip Specification

The doped diamond coating is used to harden the tip in applications that require both increased wear resistance and a conductive tip. The tradeoff for the increased lifetime is that the coating also increases the diameter of the tip. If a conductive coating is not needed, the DLC coated probes (Model# TESPD) provide a cost effective alternative.

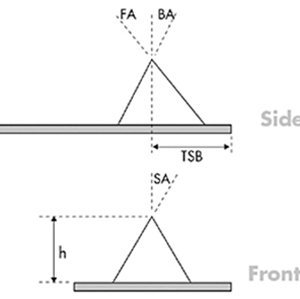

Tip Height (h): 10 - 15 µm

Front Angle (FA): 25 ± 2.5º

Back Angle (BA): 17.5 ± 2.5º

Side Angle (SA): 20 ± 2.5º

Cantilever Specification

Material: 0.010-0.025 Ωcm Antimony (n) doped Si

Geometry: Rectangular

Cantilevers Number: 1

Cantilever Thickness (Nom): 2.95µm

Cantilever Thickness (RNG): 2.20 - 3.70µm

Back Side Coating: Reflective Aluminum